Energy Efficiency in Commercial Kitchen Freezers: What You Need to Know

Key Features of Energy-Efficient Commercial Freezers

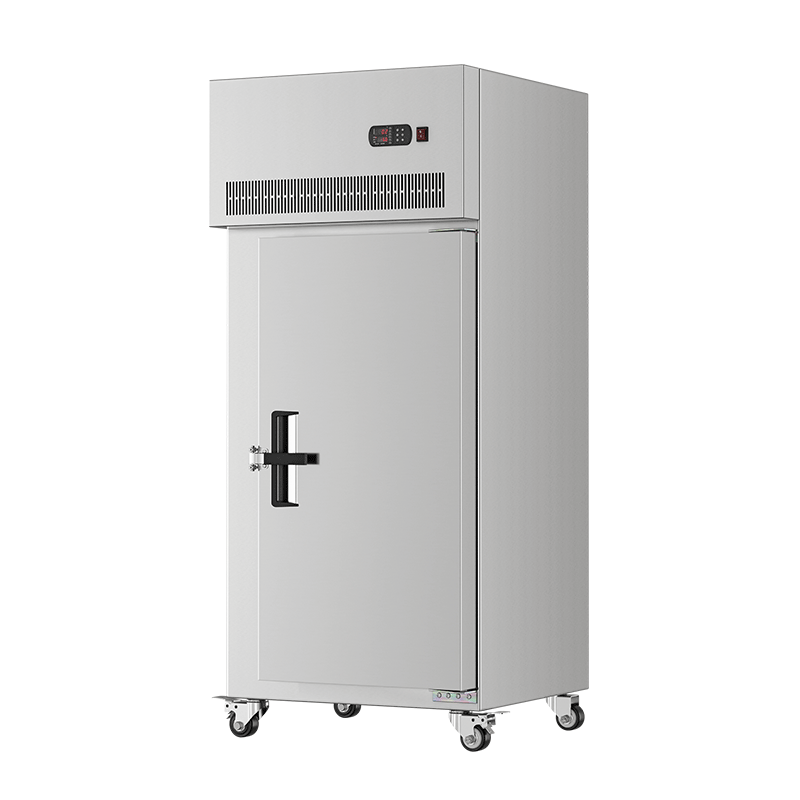

Blast Freezer -45°C (15 Plates): High-Density Insulation & Stainless Steel Design

High-density insulation is crucial for maintaining low temperatures effectively in commercial kitchen freezers, such as the Blast Freezer -45°C (15 plates). This insulation prevents heat transfer, ensuring the internal environment remains cold with minimal energy consumption. Energy-efficient compressors further enhance this process, significantly reducing electricity use while preserving food quality.

Stainless steel construction adds durability and corrosion resistance, extending the lifespan of freezers used in demanding commercial environments. Stainless steel's robust nature can withstand frequent use, making it an ideal material for commercial kitchen freezers that experience heavy-duty conditions.

According to energy standards organizations, freezers equipped with high-density insulation can achieve up to 30% energy savings compared to traditional models. This reduction in energy consumption not only benefits the environment by lowering emissions but also offers substantial savings on electricity bills over time, making it a valuable investment for any food service establishment.

Blast Freezer -45°C (22 Plates): Large Capacity with Forced Air Evaporator System

In the context of commercial kitchens, having a large capacity freezer like the Blast Freezer -45°C (22 plates) is a game-changer. With its ability to store bulk quantities, it enhances operational efficiency and ensures that large volumes of food can be frozen quickly and uniformly. This minimizes the need for multiple units, thereby conserving space and energy.

The forced air evaporator system is pivotal in optimizing temperature distribution, ensuring rapid and even freezing throughout the entire chamber. This system not only accelerates food preservation but also maintains consistency across stored items, a critical factor in food quality management.

Energy-efficient models like this freezer contribute to reduced electrical usage, especially during peak hours, aligning with sustainability goals in modern commercial kitchens. Data shows substantial reductions in energy bills when using larger, more efficient models, as these freezers are designed to optimize power use while delivering high performance.

Top Energy-Saving Strategies for Freezer Efficiency

Optimize Temperature Settings for Commercial Kitchen Freezers

Setting the optimal temperature for commercial kitchen freezers is crucial for reducing energy usage. Typically, maintaining a range between -18°C to -25°C is recommended for energy efficiency while ensuring food safety. This range maintains a delicate balance between preserving food and minimizing the freezer's workload, thus lowering energy consumption. Additionally, implementing monitoring tools, such as temperature sensors or remote management systems, can help maintain consistent settings, ensuring that energy efficiency tips for commercial kitchen freezers are effectively executed. Remote monitoring tools offer a convenient way to track temperature and adjust settings, preventing unnecessary energy use.

Seal Integrity: Inspect Door Gaskets Regularly

Maintaining seal integrity through regular inspection of door gaskets is vital for preventing energy loss. Door gaskets that are in poor condition can allow cold air to escape, forcing the system to work harder and consume more energy. Regular inspections and timely replacements of gaskets should be a key component of any maintenance strategy to maximize energy efficiency. According to energy conservation studies, properly sealed commercial kitchen freezer doors can dramatically reduce energy consumption, highlighting the importance of this straightforward, yet effective energy-saving strategy.

Strategic Loading to Improve Airflow

Proper loading of freezers is essential to enhance airflow and minimize energy consumption. Overloaded freezers can obstruct airflow, which can increase the unit's energy demand as it struggles to maintain the set temperature. For optimal loading, it's important to leave sufficient space between items to allow air circulation. Research has shown a strong correlation between adequate airflow and energy efficiency in freezers. By optimizing the arrangement of goods inside, businesses not only enhance preservation but also significantly cut down on energy costs, making this a crucial operational consideration for any commercial kitchen.

Maintenance Tips to Sustain Energy Efficiency

Routine Condenser Coil Cleaning

Maintaining energy efficiency in commercial kitchen freezers involves routine cleaning of the condenser coils. These coils play a crucial role in the refrigeration process by dissipating heat. Over time, dust and debris can accumulate, reducing the freezer's cooling efficiency and increasing energy consumption due to the cooling system working harder to maintain optimal temperatures. It is recommended to clean condenser coils at least semi-annually, using brushes or vacuum cleaners while adhering to safety protocols, such as unplugging the appliance. Experts suggest that routine cleaning can enhance energy savings, as clean coils allow the refrigeration unit to function more efficiently.

Scheduled Defrosting Practices

Scheduled defrosting is essential for preventing ice accumulation, which can impede airflow and lead to energy inefficiency in commercial freezers. Ice buildup forces the freezer to consume more energy to maintain the necessary cold conditions. It's advisable to implement a defrosting schedule tailored to the freezer's usage and load, typically every three to six months. Automated defrosting systems can be beneficial as they provide consistent defrosting cycles without manual intervention, ensuring the appliance operates efficiently. These systems can significantly reduce energy consumption by maintaining optimal temperature settings and minimizing the energy required for cooling, thereby resulting in overall operational cost savings.

FAQ

What is the significance of high-density insulation in commercial freezers?

High-density insulation prevents heat transfer, maintaining low temperatures with minimal energy consumption, which leads to up to 30% energy savings.

How does a forced air evaporator system benefit commercial freezers?

A forced air evaporator system ensures rapid and even freezing, optimizing temperature distribution and maintaining consistency in food quality.

Why are stainless steel freezers ideal for commercial kitchens?

Stainless steel offers durability and corrosion resistance, essential for frequent use in demanding commercial environments.

How can temperature settings optimize energy efficiency in commercial freezers?

Maintaining temperatures between -18°C and -25°C helps balance food preservation needs with energy efficiency goals.

What maintenance practices sustain freezer efficiency?

Routine condenser coil cleaning and scheduled defrosting are crucial for maintaining efficiency and preventing increased energy consumption.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

AZ

AZ

KK

KK

SI

SI

UZ

UZ