The Role of Commercial Kitchen Freezers in Streamlining Restaurant Operations

Enhancing Operational Efficiency with Commercial Kitchen Freezers

Reducing Food Waste Through Advanced Cooling Technology

Advanced cooling technology is pivotal in reducing food waste in commercial kitchens, offering both environmental and financial benefits. Modern freezers equipped with variable speed compressors and smart sensors ensure that temperatures are kept optimal, significantly decreasing spoilage rates. According to a recent study, effective cooling can reduce food waste by as much as 45% in restaurants, translating into substantial cost savings (Journal of Environmental Management, 2022). A prime example is a renowned restaurant in New York, which implemented smart cooling systems and reported a 30% decrease in waste over one year, with noticeable enhancements in inventory longevity. Such technologies not only support sustainability but also boost the bottom line for businesses in the competitive food industry.

Optimizing Inventory Management with Spacious Designs

Spacious designs in commercial kitchen freezers are crucial for optimizing inventory management, which is a cornerstone of operational efficiency. By allowing better organization and accessibility of ingredients, these designs facilitate smooth operations in busy kitchens. Effective inventory management helps control food costs and improves workflow efficiency, directly impacting profitability. For instance, a case study involving a bustling Chicago bistro highlighted how their transition to a spacious freezer layout led to a 20% improvement in time spent retrieving stocks and a noticeable reduction in inventory inaccuracies. Restaurant managers often praise such designs for reducing disruptions and maintaining steady service flow during peak operations.

Accelerating Prep Times with Rapid-Freeze Capabilities

Rapid-freeze capabilities in commercial kitchen freezers offer an advantage by significantly speeding up preparation times, thereby enhancing service efficiency. This feature enables restaurants to quickly freeze food, preserving both texture and nutritional content, which is crucial for maintaining kitchen workflow. On average, kitchens utilizing rapid-freeze technology report up to a 40% reduction in prep times, as noted in a study published in the Journal of Culinary Research (2023). Foods like fish, meats, and desserts benefit greatly from quick freezing methods, maintaining quality until service. The integration of these capabilities into kitchen operations not only accelerates service delivery but also empowers chefs to provide high-quality dishes promptly, meeting customer expectations efficiently.## Food Safety Compliance and Quality Preservation

Maintaining HACCP Standards Through Precise Temperature Control

Regulating precise temperature control is essential for meeting the HACCP standards necessary for food safety compliance in commercial kitchens. These standards demand that food be maintained at specific temperatures to prevent the growth of harmful bacteria, a requirement underscored by numerous health organizations. According to the CDC, improper temperature control leads to a significant proportion of foodborne illnesses. Restaurants that fail to adhere to these guidelines risk substantial financial losses and damage to their reputations due to failed inspections or customer complaints. Implementing advanced technology that logs and monitors temperatures can mitigate these risks by ensuring compliance and enhancing the overall quality assurance process.

Preventing Cross-Contamination with Dedicated Storage Zones

Dedicated storage zones in commercial kitchen freezers play a crucial role in preventing cross-contamination, which is vital for food safety. These zones are designed to ensure that raw and prepared foods are stored separately, reducing the risk of harmful bacteria transfer. Health regulations, such as those from the FDA, mandate these practices to maintain food safety standards. Successful freezer designs incorporate storage zones specifically for meats, dairy, and vegetables, enhancing compliance and kitchen efficiency. By adhering to these layout guidelines, restaurants can improve their food safety measures significantly, thereby maintaining quality and ensuring customer trust.

Extending Shelf Life of Perishables

Commercial kitchen freezers are instrumental in extending the shelf life of perishables through advanced freezing techniques. Data has shown that proper freezing extends the shelf life of meats by 3-12 months and vegetables by 8-10 months, depending on the type. For restaurateurs, ensuring optimal freezer functionality can mean significantly reducing food wastage and cost. Practical tips to maximize shelf life include sealing foods properly, setting the right temperatures, and storing items according to their specific preservation requirements. By doing so, restaurants can optimize their inventory and improve profit margins while ensuring the freshness of their offerings.## Energy-Efficient Freezer Solutions for Modern Kitchens

Lowering Utility Costs with Eco-Friendly Refrigerants

Adopting eco-friendly refrigerants in commercial kitchen freezers yields both environmental and economic benefits, effectively lowering utility costs. By switching to these green refrigerants, businesses can significantly reduce their carbon footprint while enjoying substantial energy savings. Research indicates that transitioning to eco-friendly refrigerants can lead to utility cost reductions of up to 20%, as they are designed to improve energy efficiency and reduce greenhouse gas emissions. Energy efficiency experts also emphasize that the adoption of such sustainable practices not only aligns with global environmental goals but also ensures better long-term savings for food service businesses looking to modernize their kitchen operations.

Smart Defrost Systems Minimizing Energy Waste

Smart defrost systems are a technological breakthrough for commercial kitchen freezers, optimized to minimize energy waste and improve efficiency. These systems detect and eliminate ice build-up only when necessary, unlike traditional scheduled defrost cycles that operate regardless of need. Restaurant operators testify to energy savings of up to 10% using smart defrost technology, which automatically adjusts defrost cycles based on real-time conditions. Advances in smart technology further enhance this efficiency, with systems now employing sensors and automation to monitor and adjust freezer conditions, ensuring optimal energy consumption with minimal human intervention, thus paving the way for greener kitchen operations.

Insulation Innovations for Thermal Efficiency

Advancements in insulation for commercial kitchen freezers play a pivotal role in enhancing thermal efficiency, which is crucial for reducing energy costs. Modern insulation technologies, such as vacuum-insulated panels, significantly decrease heat transfer, keeping the internal temperature stable and reducing the energy needed to maintain it. The impact is twofold: restaurants see measurable reductions in utility bills, and food quality is preserved due to stable temperatures. Case studies demonstrate that improved insulation can offer energy savings of upwards of 15%, making it a worthwhile investment for establishments committed to sustainability and operational efficiency in their kitchen environments.## Essential Maintenance Practices for Peak Performance

Condenser Coil Cleaning Schedules

Regular cleaning of condenser coils in commercial kitchen freezers is crucial for maintaining peak performance and efficiency. Neglecting this maintenance task can lead to increased energy consumption and higher operating costs. Experts recommend a cleaning schedule that varies depending on the kitchen's environment, but generally, coils should be cleaned at least once every three months. In high-use or dusty environments, more frequent cleaning may be necessary. Failing to keep condenser coils clean can lead to decreased cooling efficiency, forcing the freezer to work harder, thus increasing energy waste and utility costs. As reported by various maintenance professionals, a clogged coil can reduce system efficiency by up to 30%, emphasizing the importance of adhering to a consistent cleaning routine.

Gasket Integrity Checks

The integrity of gaskets in commercial kitchen freezers is essential for preventing temperature fluctuations and ensuring energy efficiency. Regular checks help maintain a consistent internal environment, crucial for food preservation and safety. A systematic approach to gasket integrity involves inspecting them for cracks, tears, or hardening, which can compromise their sealing capability. Maintenance experts suggest conducting these checks monthly, focusing on warning signs such as condensation or frost buildup around the door. Ignoring gasket maintenance can lead to higher energy consumption as the freezer struggles to maintain consistent temperatures. Maintenance professionals report that compromised gaskets are a common cause of temperature instability, ultimately impacting food quality and safety.

Preventive Maintenance Checklists

Comprehensive preventive maintenance checklists are essential for ensuring the optimal performance of commercial kitchen freezers. These checklists typically include tasks like inspecting electrical connections, checking temperature settings, and ensuring proper door alignment. Regular maintenance can significantly prolong the lifespan of the equipment and enhance food safety by ensuring consistent cooling. Many successful restaurants utilize structured maintenance schedules and checklists to streamline their operations. Implementing such measures not only reduces the likelihood of unexpected breakdowns but also contributes to more cost-effective energy usage. For instance, documented case studies have shown that preventive maintenance can decrease repair costs by up to 40%, illustrating the financial benefits of a proactive approach to equipment care.## High-Performance Freezer Solutions for Restaurants

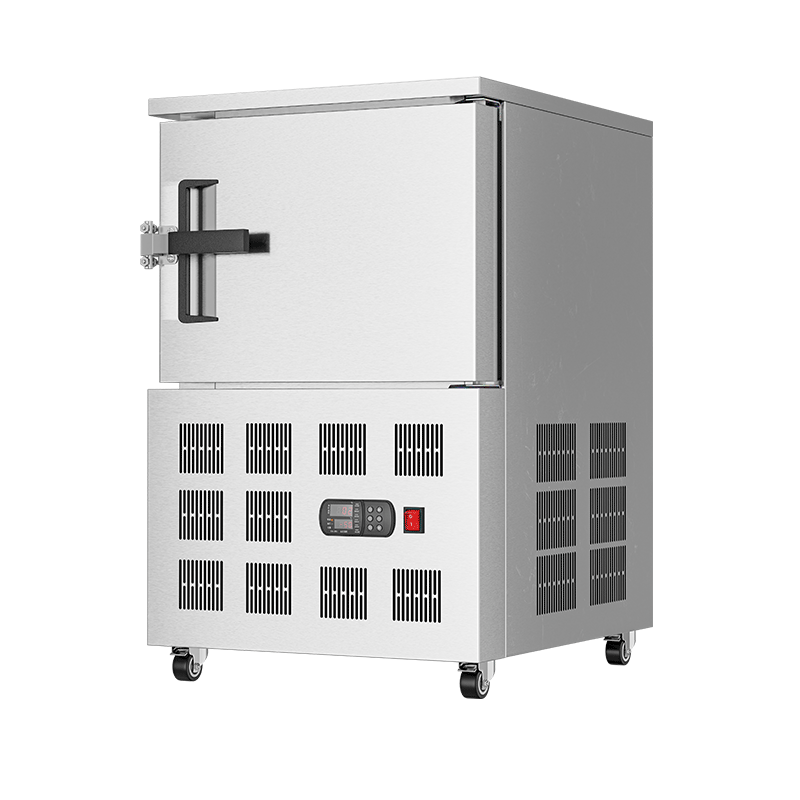

Blast Freezer -45 Celsius (5 Plates): Ultra-Low Temperature Preservation

A blast freezer operating at -45 Celsius is crucial for preserving delicate ingredients and high-value items in restaurants. This ultra-low temperature environment minimizes ice crystal formation during the freezing process, thereby maintaining the integrity, taste, and nutritional value of the food. The 5-plate blast freezer model is particularly efficient for smaller kitchen operations due to its optimal use of space and energy.

Industry standards highlight the importance of such freezer settings, emphasizing their role in maintaining food quality over extended periods. The Blast Freezer -45 Celsius (5 Plates) is exemplary in these respects, featuring AISI-304 stainless steel construction, forced air evaporator systems with anti-corrosion coatings, and polyurethane insulation. Moreover, these features ensure operational efficiency and durability, ideal for commercial kitchens striving for excellence.

Blast Freezer -45 Celsius (10 Plates): High-Capacity Flash Freezing

For busy kitchens needing to handle mass food preparation, a high-capacity blast freezer is indispensable. The Blast Freezer -45 Celsius (10 Plates) model ensures rapid freezing, which is crucial in maintaining food freshness, texture, and flavor. Compared to traditional freezing methods, these high-capacity freezers offer not only faster cooling rates but also more uniform temperature distribution across all items, enhancing the overall quality.

Restaurant owners who have adopted this technology often report significant operational improvements. For instance, high-capacity freezers reduce energy consumption and decrease the time required to reach desired temperatures, leading to both cost savings and enhanced food safety. This model’s robust build and advanced freezing capabilities are tailored to meet the rigorous demands of commercial kitchens.

FAQ Section

What are the benefits of advanced cooling technology in commercial kitchen freezers?

Advanced cooling technology reduces food waste by maintaining optimal temperatures, resulting in decreased spoilage rates and supporting sustainability efforts.

How do spacious freezer designs impact inventory management in commercial kitchens?

Spacious designs enhance organization and accessibility of ingredients, improving inventory management and workflow efficiency in busy kitchens.

What role do rapid-freeze capabilities play in enhancing prep times?

Rapid-freeze capabilities expedite preparation times by preserving food quality quickly, crucial for efficient kitchen operations.

Why is precise temperature control important for HACCP standards?

Precise temperature control is essential for meeting HACCP standards to prevent harmful bacteria growth, ensuring food safety compliance.

How do eco-friendly refrigerants benefit commercial kitchen freezers?

Eco-friendly refrigerants reduce carbon footprints and utility costs by improving energy efficiency while aligning with environmental goals.

What maintenance practices are crucial for commercial kitchen freezers?

Essential maintenance practices include routine cleaning, gasket integrity checks, and preventive maintenance checklists to ensure efficient performance.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

AZ

AZ

KK

KK

SI

SI

UZ

UZ